Breadcrumb navigation

3D Point Cloud Analysis Technology

1.Introduction

In recent years, the distance to be measured by 3D sensors and "3D point cloud processing" technology that can measure size, position are attracting attention.

In particular, the popular use case of 3D sensors as an example, safety management is realized by using 3D-lidar to realize autonomous driving of cars, acquiring information around the car as 3D point cloud data, and analyzing and grasping the recognition and location information of forward vehicles and pedestrians. Additional infrastructure maintenance and inspections are widely used mainly for safety management at construction sites and inventory management such as logistics warehouses.

Recently, sensors for acquiring 3D point cloud data and technological developments such as algorithms and due to performance improvement and price reduction, 3D point cloud data in space has been utilized in various forms, and it has become a trending technology that is expected to be applied to autonomous driving, robot vision, and machine vision.

2.What is 3D point cloud data?

A point cloud means a collection of points, typically expressed in three-dimensional coordinates (x, y, z). 3D point cloud data is a collection of coordinates (x, y, z), and pcd as a file formatandThere are various formats such as ply.

3D point cloud data can be acquired by 3D sensors, and 3D sensors are mainly as follows.

- 3D-LIDAR(Light Detection And Ranging)

- ToFcamera(Time of Flight)

- Stereo camera

- 3D scanners

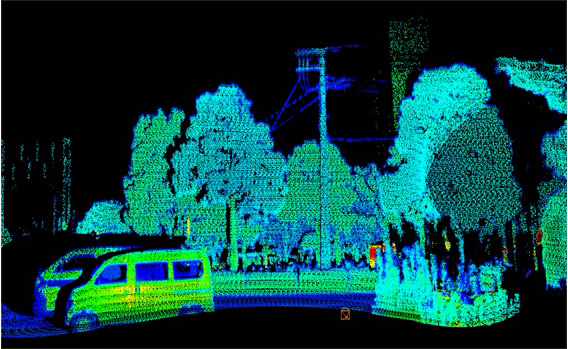

Figure 1 is an example of 3D point cloud data obtained by 3D-lidar. In the shooting data, you can see the car, trees and poles, but these are composed of a collection of coordinate (x,y,z) points.

3.What is "3D point cloud processing" technology?

The 3D point cloud data acquired by the 3D sensor is a dedicated viewer attached to the 3D sensor. Figure 1 three-dimensional 3D data can be visualized so that, however, the space captured by the 3D sensor is only visualized. Visualization data directly is linked to the customer's business.

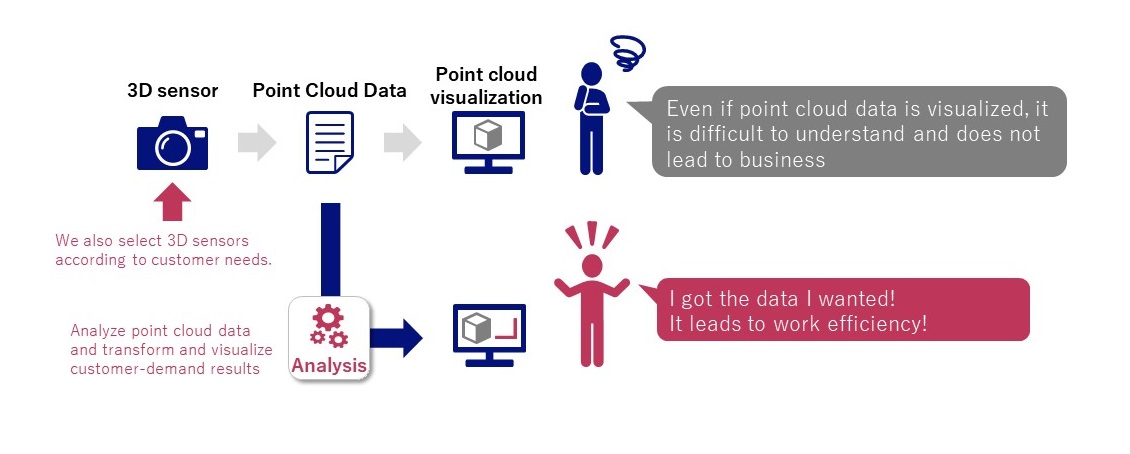

Therefore, "3D point cloud processing" technology is required for analyzing 3D point cloud data. Point Cloud Library (PCL) (*), which is a popular open source software library for processing 3D point clouds. Data taken by utilizing this PCL, machine learning, and mathematical knowledge, it is necessary to implement the technology to help visualize, measure, and automate and improve efficiency of 3D point cloud data .

(※)PCL: https://pointclouds.org

https://pointclouds.org

An example of "visualization/measurement/automation" is shown below.

- Visualization: Visualize ""3D point cloud data"" as numerical data of coordinates as a 3D image

- Measurement: Measure the height of the telephone pole and measure the size of the luggage in the warehouse from the visualized 3D point cloud data

- Automation: Automatically find utility poles and find people at construction sites from visualized 3D point cloud data.

By simply purchasing a 3D sensor, visualization of 3D point cloud data is possible. It detects objects on telephone poles and automatically measures the height of the poles, and automatically detects workers (people) working at construction sites. In order to raise an alarm when entering a dangerous area, it is essential to analyze and convert 3D point cloud data to the results required by the customer.

4.Conclusion

This time, we introduced "3D point cloud processing" technology using 3D sensors.

"3D point cloud processing" technology is used in and it is expected to realize operational efficiency and automation, focusing on safety management at construction sites and in inventory management such as logistics warehouses.

In NEC Communication Systems, as a space recognition solution utilizing 3D sensors, we propose a solution that solves customers' problems by recognizing the space and objects existing in the space and converting it into information that is valuable to the customer.

We are introducing load capacity visualization technology and separation measurement technology that utilize the 3D sensor.