Breadcrumb navigation

NEC Marker Positioning Software

Easily acquire high-precision location information

Use case

Inventory Management

Due to the decrease in the working population and the use of smart factories, manufacturing sites, such as factories, are becoming more automated. In addition to automating the production line, it is also important to manage the inventory and position of finished products, and it is possible to prevent unnecessary production of products such as overstocking. You can also manage intermediate parts as well as finished products. It also prevents the loss of intermediate parts and the resulting rebuilding, leading to increased productivity.

Monitoring of mobile equipment

Logistics warehouse forklifts and various mobile equipment such as trucks at manufacturing sites are active in the production process. By accurately getting the location of the moving equipment in real time, it becomes a more efficient operation. In addition, by managing the flow line of the moving equipment, the elimination of blockage in the area and optimization of the running route can be realized.

In addition

It can be widely used in situations that require high-precision position information such as AGV control and storage position of equipment.

Higher accuracy and lower cost than RFID and beacons, easier than QR codes

Acquire AR marker location information with high accuracy

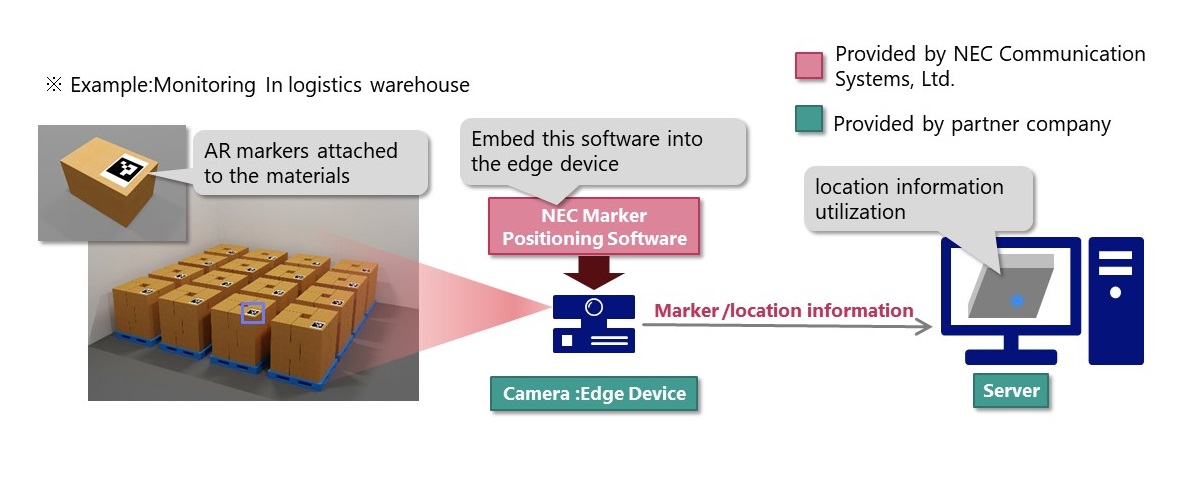

Location information is acquired by using a camera to photograph AR markers attached to the materials and equipment. By relatively obtaining the position of the AR marker from the position and orientation (angle) between the AR marker and the camera, the position is estimated with high accuracy within 50cm *. In addition, by continuously acquiring the position based on images taken with AR markers, it is possible to capture the movement status of materials and equipment while moving, and it is possible to monitor the movement of materials and equipment in real time.

Easy to handle and easy to maintain

Since AR markers on paper-like media are attached to materials and equipment, and the position is can be estimated by taking a picture with a camera, it is not necessary to attach a device to materials such as beacons, which was necessary for the radio wave method, and handling is easy. In addition, maintenance such as battery replacement is unnecessary, and serviceability is excellent.

Seamless positioning indoors and outdoors

By using markers for wind and rain-resistant media, it is possible to estimate the position even outdoors. Since it is not necessary to prepare different positioning devices (beacons, GPS, etc.) for indoors and outdoors, location information management can be centralized.

Simultaneous acquisition of multiple location information with a single camera

Since the location information of multiple AR markers can be acquired at the same time in a single shooting, there is no need to read them one by one. Since the number of stocks can be checked in one shot, the time for inventory confirmation can be shortened.